Processes

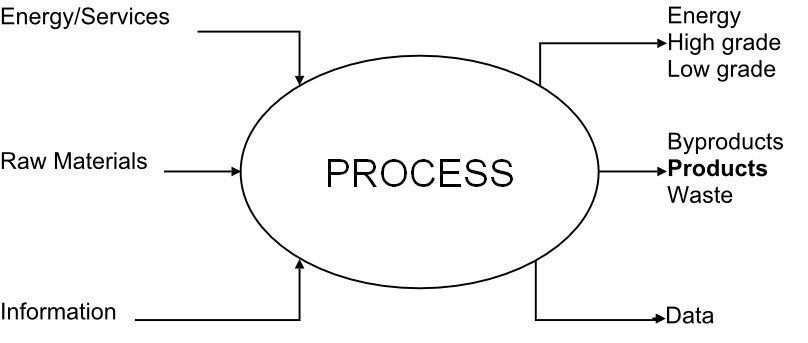

The fundamental description of a production process is shown in figure below.

Raw materials provide the basic feedstock input to the process. These materials are often the output of other production processes. The process is designed to produce a specified product or range of products. Inevitably as no process is 100% selective, some useful byproducts and unwanted byproducts (waste) are formed.

The process will require an energy input such as a hydrocarbon fuel, electricity or steam. Some of this energy will be lost to the environment as low grade (low temperature) heat. In some cases any surplus energy can be recovered as high grade energy.

Information (eg instructions or computer code) is required to control the process. The process monitoring systems will generate data.

An example of an industrial process would be electricity generation from coal. Here the raw material is coal, extracted from the earth, and the primary output is high grade electricity. Generating plants also produce CO2, ash from mineral impurities in the coal, and low grade waste heat, the water vapour plumes from the cooling towers. Any sulphur in the coal burns to SO2 which can be removed from the waste gases.

On a domestic scale, one can imagine cooking a meal. The raw materials are the food ingredients (eg meat, vegetables, fats, cereals etc). The main product is clearly the meal on the plate. The waste might include vegetable peelings , surplus food or food sticking to the utensils. High grade energy, either electricity or gas, is used for food processing, cooking and washing up. This energy is often lost to the environment eg heat losses from the oven or from the cooked food.

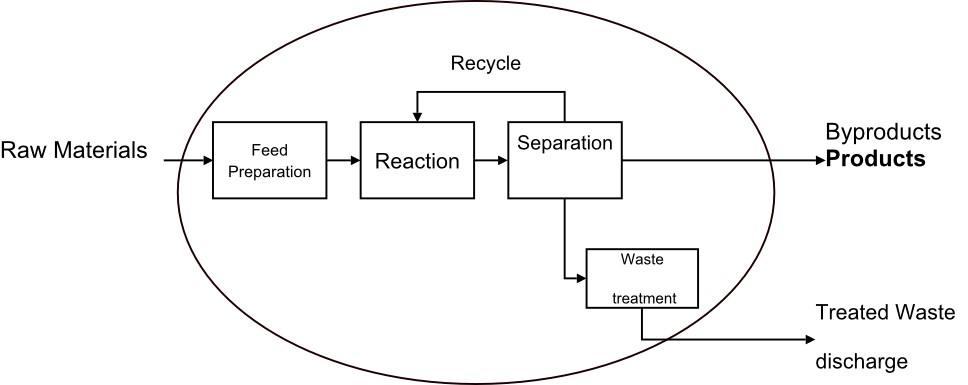

A chemical plant is another example of a production process. The following figure illustrates some of the very basic stages in chemical plants.

Raw materials, which again can include products from other processes, are reacted together to produce a range of desired product(s) and byproducts together with any unreacted feeds. This mixture is fed to a set of separation units to recover products, to recycle useful components where possible, and to extract waste streams for treatment before discharge to the environment. In reality, a chemical process will incorporate other stages (eg feed purification and storage) and use a variety of services and support materials (eg catalysts).

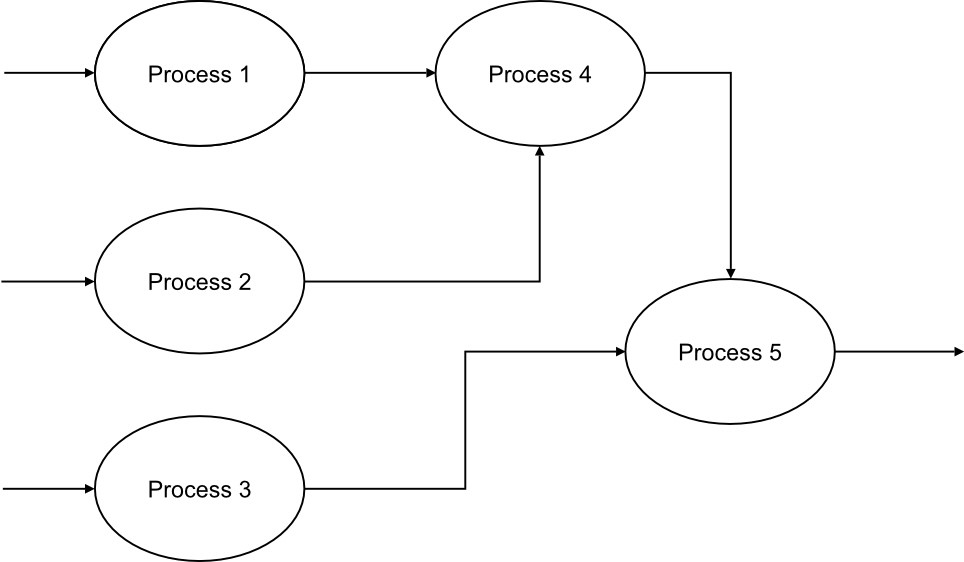

Processes invariably interact with other processes. The outputs (products) are often feeds to other processes. Indeed the process and manufacturing chain all stops when it reaches the final consumer. See figure below.

An example of a set of processes would be the production of ‘poly bags’. Oil refineries import oil and natural gas extracted from below ground and, among other products such as petrol and diesel, manufacture ethylene (C2H4 a gas). The ethylene is the feedstock to polymerisation plants manufacturing solid polyethylene polymer. This solid is then fed to a bag manufacturing plant and, using blown film extrusion, millions of shopping bags are made.

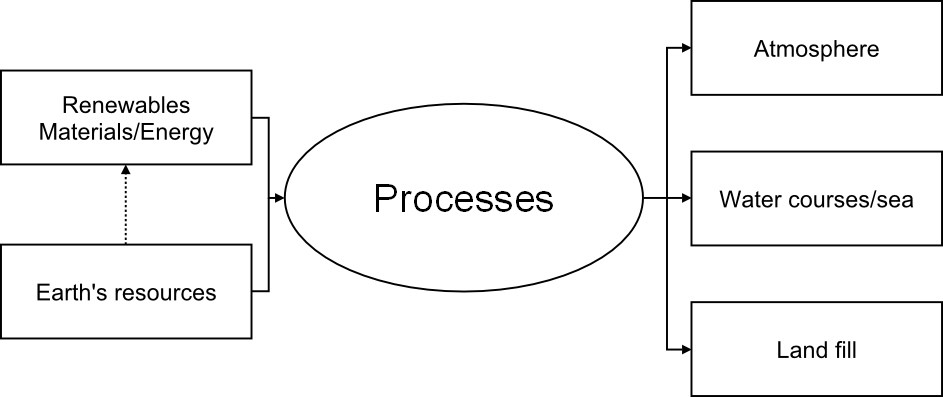

One can also take a global perspective for all processes. The raw materials are predominantly extracted from below the earth’s surface. These materials, which can be used as feedstocks for production processes or used to generate power, include mineral ores, limestone, sand, coal, oil, natural gas etc. Renewable supplies include agricultural crops and solar or wind energy.

As noted before, the manufacturing process will produce waste products. The final consumer will also produce waste. Although a moderate amount of unwanted material can be re-used or recycled, the products originally sourced from the earth inevitably return to the environment either as landfill, or, say after incineration or water treatment, discharge to the atmosphere or to the sea.